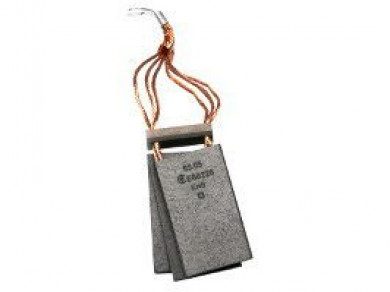

Carbon Brushes for DC motors

DC motor brush grades

Mersen offers a wide range of electrographitic brushe grades, particularly adapted to DC motors, such as the world-renowned EG34D and 2192 brush grades.

Electrographitic grades are prepared from carbon powders and coke; they are then subject to high temperature thermal treatments (>2500 °C) to transform the basic amorphous carbon into artificial graphite, and enhances physical properties of the grades.

Carbon Brushes to meet your requirements

Our research efforts result in brush materials which provide better commutating ability, longer life, and reduced commutator maintenance. Mersen produces advanced brush grades for service conditions ranging from high loads to low loads, contaminated environments (chemicals, moisture, oil vapors), and other difficult operating conditions. Graphite grades that meet your requirements can thus be readily selected from our variety of materials. Please refer to Mersen’s Technical Guide "Carbon brushes for motors and generators" for further information.

Mersen, a reference supplier of electric motor manufacturers, also offers dedicated services of refurbishment, replacement of brushes and brush-holders, re-engineering and trainings.

DC motors carbon brushes: main features

Mersen is capable of supplying you with carbon brushes of various designs, shapes and sizes, with high quality of manufacturing. When required, we could adjust the design (grade, cable, top pad, wafer size…) to adapt the carbon brush specifically to your DC motor application.

Operations of brushes can be optimized by enhancing their mechanical stability (shape, components, friction coefficient), electrical performances (voltage drop at contact, commutation ability, load capacity), and reducing their sensitivity to environmental condition (protecting / polishing / lubricating action on the commutator skin), etc. The function of a good brush is further explained in our technical data sheet reference TDS 01.

In addition, Mersen offers solutions for alerting users on brush wear (indicator devices, linked to the brush or to the brush-holder), or, to go even further, monitoring operational parameters with our complete solution MERSEN Total Monitoring.

As a summary, Mersen’s carbon brushes main features are:

- Specific designs

- Selected grades

- High quality tamping

- Optimized cable dimensions

- Good mechanical stability

- Low friction coefficient

- Adapted range of current density

- High transient current load capacity

- Good acceptability for commutation

- Wide speed range (from 15 m/s to 55 m/s)

Carbon Brushes for DC motors: applications

Carbon brushes from Mersen lead the way in many adverse applications of DC motors such as: traction (locomotives, metros, mining…), lifting (forklifts, cranes, elevators…), conveyors (mining, cement and metalworking industries), extruders (plastics, metallurgy), and also winders, ventilators, pumps, etc.

Click on links below to discover our range of products for each market:

- Electric and Diesel Electric Locomotives (traction motors)

- Transit & Metro (traction motors of metros, tramways or trolleybusses)

- Aerospace (auxiliary motors)

- Metallurgy (rolling mills, winders, wire drawing machines, extruders, winding machines)

- Paper plants (paper machines, winders)

- Cement plants (furnace motors, ventilators, ground or aerial conveyors)

- Plastic Industry (extruders)

- Forklifts (lifting motors, traction motors)

- Mining (draglines, shovels, wheel motors for front loaders and trucks, conveyors)

- Ports & marine (lifting motors for cranes and gantry cranes, propulsion motors, onboard motors)

- Oil & gas (drilling, lifting, pump and anchor motors)

- Elevators (lifting)

- Ski lifts (motors)

Related Products

Contact USA

Sales & Engineering

07005 Boonton, NJ

+1 800 526 0877

Sales & Engineering

F-80084 Amiens

+33 (0)3 22 54 45 00

Sales & Engineering

Annekal Taluk

560099 Bangalore, Karnataka

+91 803 094 6121

碳刷, 刷架, 滑环组件, 工业受流 电机和发电机的电气解决方案

Sales & Engineering

5 andar- Cj. 502.

Bairro Mirandópolis

CEP: 04046-500

+55 11 2348-2360

Contact USA

Sales & Engineering

07005 Boonton, NJ

+1 800 526 0877

Sales & Engineering

F-80084 Amiens

+33 (0)3 22 54 45 00

Sales & Engineering

Annekal Taluk

560099 Bangalore, Karnataka

+91 803 094 6121

碳刷, 刷架, 滑环组件, 工业受流 电机和发电机的电气解决方案

Sales & Engineering

5 andar- Cj. 502.

Bairro Mirandópolis

CEP: 04046-500

+55 11 2348-2360

Product Literature

PTT-TDS-01 - The functions of a good brush what you should know

Download540.15 KB

PTT-TDS-01 - The functions of a good brush what you should knowPTT-TDS-01 - The functions of a good brush what you should know

Download540.15 KB

PTT-TDS-01 - The functions of a good brush what you should know