Graphite Block Heat Exchangers

Mersen has designed and manufactured block heat exchangers for over 50 years, with more than 10,000 units in service around the world. Mersen offers heat exchangers in both cylindrical and cubic designs, and feature Graphilor® 3, our exclusive trademark graphite which is produced in-house.

Graphilor®3 is highly resistant to corrosion and provides a maximum temperature resistance of 400°C. It is the only impregnated graphite resulting from the combination between isostatic graphite and a specific resin and offers excellent refractory qualities and mechanical properties. Additionally, our PTFE (XTH) impregnation provides additional resistance to corrosion. Flexible designs are available to meet the needs of multiple applications.

Benefits of Mersen graphite block heat exchangers:

- High corrosion resistance of Graphilor® 3

- Compactness

- Robustness

- Modular design

- Easy maintenance

- Long lifetime

- Service and maintenance in the US with two strategically located facilities

- Manufacturing plant in the US

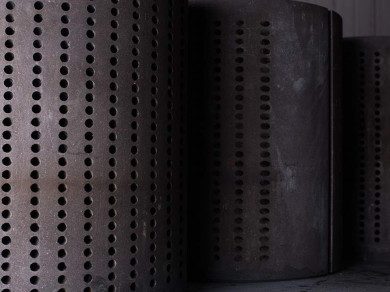

POLYBLOC®, MERSEN’S CYLINDRICAL HEAT EXCHANGERS KEY FEATURES:

LARGE HEAT TRANSFER AREAS WITH MODULAR DESIGN

- Large exchange surface areas (up to 300 m2) with high heat transfer

- Headers available in Graphilor®, stainless steel, reactive metals, PTFE or rubber lined steel

- Large range of block sizes from 140 to 1,500 mm diameter

- Design for high pressure up to 16 barG (service) and 12 barG (process)

- PTFE Bellows – fitted to graphite nozzles

- Drilling adapted to process constraints with large diameter holes for fouling process

- Multi-pass arrangements possible for both process and service sides

- Rigilor® treatment to protect the surface of the blocs against erosion in some abrasive processes

EASY MAINTENANCE DUE TO EASY DISMANTLING OF SYSTEM FOR OVERHAUL, CLEANING AND VALIDATION

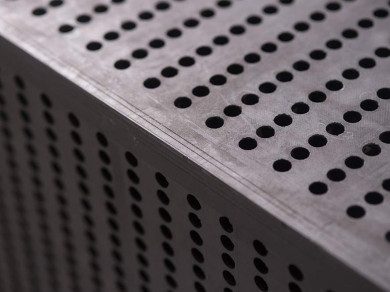

MERSEN'S CUBIC HEAT EXCHANGERS KEY FEATURES:

COMPACT DESIGN WITH SLOTS OR DOUBLE DRILLING ON PROCESS SIDE

- Effectively doubles the process side surface area making units ideal for condensing

- Drilling adapted to process requirements (6.5, 10 and 16mm holes in single or double drilling patterns)

SPECIAL GMP DESIGN FEATURES

- Fully draining with no process to service gaskets

FLEXIBLE AND EFFICIENT DESIGN

- Headers available in Graphilor®, carbon and stainless steel, PFA, PTFE or rubber lined steel

- No hidden gaskets, single piece core blocks (250, 400, 500 & 600mm square and up to 1800mm long)

- Heat exchange areas from 1m2 to 100m2

- Design pressure of up to 10 barG on process and service side

- PTFE Bellows are fitted to graphite nozzles to remove pipework stresses

- Interchanger provides the most optimum solution for corrosive fluids on both process and service side

- Multi pass arrangement provides the most efficient thermal design using true counter-current flow, on both process and service side

EASY MAINTENANCE DUE TO EASY DISMANTLING OF SYSTEM FOR OVERHAUL, CLEANING AND VALIDATION

Ask us for an extensive list of market applications, such as phosphoric acid evaporators, sulfuric acid heaters, hydrochloric acid re-boilers.

Contact USA

Sales & Engineering

Salem, VA 24153

(540) 389-7535

Contact USA

Sales & Engineering

Salem, VA 24153

(540) 389-7535