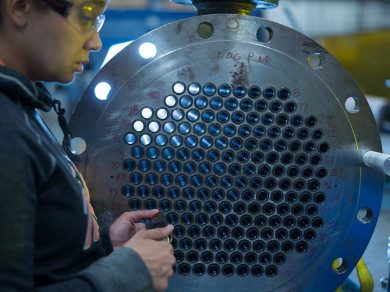

Tantalum Heat Exchanger Manufacturer

Mersen is recognized as a worldwide expert in the thermal and mechanical design of industrial heat exchangers.

Mersen’s experience in the design, forming and welding of Tantalum equipment, combined with an international material sourcing policy, allows Mersen to provide quality, cost-effective solutions that provide higher yields, lower maintenance costs and longer product lifetime.

Tantalum heat exchangers are mainly used in high-corrosive environments within the chemical and pharmaceutical industries. Due to the unique chemical and physical properties of Tantalum, specific equipment and highly trained engineers are required. Mersen produces Tantalum heat exchangers in its dedicated workshop in Germany and in the US. Mersen Linsengericht, the home of Tantalum, is deemed to be the worldwide leader for the manufacture of Tantalum equipment. Mersen’s state-of-the-art tantalum solutions are highly corrosion-resistant and comparable to glass-lined equipment.

MERSEN TANTALUM HEAT EXCHANGERS ARE HIGHLY CORROSION-RESISTANT TO:

- Hydrochloric acid

- Nitric acid

- Sulfuric acid

- Phosphoric acid

- Acid concentration

- Strong organic acids

- Bromine

- Pickling baths

- and mixtures of any of the above

Tantalum is competitive to glas-lined equipment.

Key features:

Comprehensive Tantalum heat exchangers portfolio (the following data are for reference, they do not show the limits)

- Bayonet heaters: up to 290 tubes, DN 1,350, 40 m2 heat exchange surface

- Shell and tubes heat exchangers: up to 580 tubes, DN 800, 202 m2 heat exchange surface

- U-tube heat exchangers: up to 490 tubes, 317 m2 heat exchange surface

- Heating coils of Tantalum for columns with DNup to 1,000

- Cladded tube sheets

- Welded plate heat exchangers

Customer benefits:

- Recognized experience in Tantalum forming

- Design according to international standards

- Material according to ASTM, EN

- Dedicated 3 000 m2 workshop “Home of Tantalum”

- Experienced and qualified welding teams

- Proven quality system

- Local service

Mersen produces high-end Tantalum heat exchangers in its dedicated 3,000 m2 workshop in Germany and 6,000 m2 in the USA.

Contact USA

Sales & Engineering

Salem, VA 24153

(540) 389-7535

Contact USA

Sales & Engineering

Salem, VA 24153

(540) 389-7535