TA/Reactive Metal Equipment and Repair Center

Mersen's service center and fabrication facility, strategically located in Salem, VA, provides a complete spectrum of production and repair capabilities.

With more than 96,000 square feet of combined fabrication and machining area, Mersen offers services on-site for planned maintenance or emergency outages.

- 96,000 sq ft repair shop

- 6,000 sq ft dedicated climate-controlled Ta/RME area

- Certified Code Repair Facility

- ASME section VIII "U" stamp and NBIC compliant

- Inventory of Ta, Zr and Ti Tubing and Sheet & Plate to support repair work

4 recent jobs

Tantalum Heat Exchanger Retube And Repair

Complete overhaul of other manufacturers' tantalum shell and tube exchanger that had over 10% tube failure.

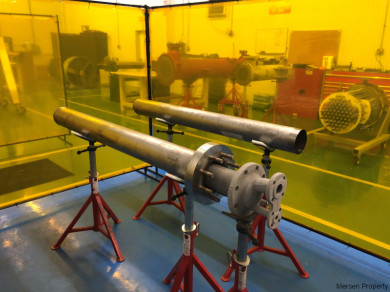

Pipe Spools

Pipe spools fabricated from titanium grade 7 for a lethal service application with 100% radiography testing.

Acid Injection Nozzle

Acid injection nozzle fabricated from zirconium 702 and heat treat annealed

Tantalum Lined Channel Head Repair

Tantalum lined condenser channel experienced cyclic fatigue which lead to a cracked liner at stay bolt location. Liner was removed for thorough repair and reinstalled utilizing all existing material.

Salem, Virginia on-site and field services

Services offered:

- Visual inspections, testing, reporting of findings

- Reactive Metal equipment welding and fabrication

- Reactive Metal piping welding

- Repair of solid, lined, cladded RME equipment

- Retubing and repair of RME heat exchangers

- Repairs of other RME components and parts such as piping spools, injection nozzles, lined heads, lined plates

- Hydro, air/soap, helium leak testing, dye penetrant inspection

- Machining

- Heat treat oven

- Engineering calculations, drawings & design expertise

Field Services: |

Materials: |

|

|

Salem, Virginia team

Contact USA

Sales

Gonzales, LA 70737

(540) 378-0324

Contact USA

Sales

Gonzales, LA 70737

(540) 378-0324

Product Literature

Anticorrosion Equipment - Service centers North America

Download1.2 MB

Anticorrosion Equipment - Service centers North AmericaAnticorrosion Equipment - Centros de Servicio Sudamérica

Download791.88 KB

Anticorrosion Equipment - Centros de Servicio SudaméricaAnticorrosion Equipment - Service centers North America

Download1.2 MB

Anticorrosion Equipment - Service centers North AmericaAnticorrosion Equipment - Centros de Servicio Sudamérica

Download791.88 KB

Anticorrosion Equipment - Centros de Servicio Sudamérica