Brush gear enclosing solutions for generators and alternators

Mersen’s innovative enclosure solutions for generators

With more than 120 years of experience of designing, manufacturing, and supplying excitation system components, Mersen is providing a new generation of dedicated high-speed turbo generator brush gear. For reliability and safety of high power, high speed machine, Mersen designed a new concept of fully integrated modular brush gear to meet the performances and safety requests of electrical energy suppliers.

High engineering level at the service of the performance

Whatever the needs, for new generator project, retrofit or renovation of old one, Mersen’s research studies group performs ventilation calculations for slip ring and carbon brushes cooling, and vibratory tests of the complete brush gear. Electrical and mechanical simulations are carried out on the state-of-the-art tests stands in our electrical laboratory.

Fitted on robust brush rocker, our plug set brush-holders with the silver multi-contact design ensure optimum current distribution between all the carbon brushes, negating the effect of potential harmful selective action.

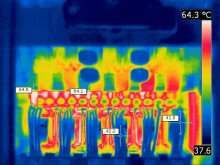

Our LFC554 carbon brushes, able to work at 100m/s, will provide you a full performance at high speed and combine a moderate wear and temperature.

Monitoring systems for brush wear, temperature and humidity level inside the enclosure can be added as needed.

Mersen, a solid innovation partner with OEMs

Our engineering teams are working closely with all the OEMs to study and propose the most appropriate design in link with performances and safety for operators.

A Mersen brush gear is a complete solution package:

- Metallic box enclosure according high safety standards

- Ventilation box customized with optimisation of air flow

- Slip ring assemblies

- Brush rocker with plug set brush-holder

- LFC554 brush set

- International standards (ISO9001, IEC, NEMA, ASTM, SAE, DIN)

- Special packaging for shipment

High safety level for operators

From 10 to 1200MW, all our brush gear system is designed with safety in mind. The watertight brush gear housing can include a ventilation system and are fitted with access to windows for visual control, as well as easy safe maintenance.

With our plug set technology, the maintenance personnel are not required to meet the energised or rotating parts of the assembly.

Operators’ safety is heightened using Mersen plug set brush holders, which guarantee full protection when replacing carbon brushes during operation.

Mersen Brush Gear Lift-up system

If you need to lift-up the carbon brushes when no power supply is needed, but rotation can’t be stopped, we have the solution. Our BB1290 & BB2156 are done for you!

An electrical motor is connected to a mechanical rod set to put and remove brushes to/from slip rings in case of power supply need.

Mersen retrofit, a unique know-how

Our expert operates every day in thermal and nuclear power plants to analyse the machines in operation included the brushes, slip-rings set and brush rocker performances. With our long experience, the know-how and capabilities to analyse the actual brush gear including brushes performance. We offering to customer, a redesign or retrofit on the existing brush gear to a new one to have better performance including more safety for operators.

Contact USA

Sales & Engineering

07005 Boonton, NJ

+1 800 526 0877

Sales & Engineering

F-80084 Amiens

+33 (0)3 22 54 45 00

Sales & Engineering

Annekal Taluk

560099 Bangalore, Karnataka

+91 803 094 6121

Sales & Engineering

碳刷, 刷架, 滑环组件, 工业受流 电机和发电机的电气解决方案

Sales & Engineering

5 andar- Cj. 502.

Bairro Mirandópolis

CEP: 04046-500

+55 11 2348-2360

Contact USA

Sales & Engineering

07005 Boonton, NJ

+1 800 526 0877

Sales & Engineering

F-80084 Amiens

+33 (0)3 22 54 45 00

Sales & Engineering

Annekal Taluk

560099 Bangalore, Karnataka

+91 803 094 6121

Sales & Engineering

碳刷, 刷架, 滑环组件, 工业受流 电机和发电机的电气解决方案

Sales & Engineering

5 andar- Cj. 502.

Bairro Mirandópolis

CEP: 04046-500

+55 11 2348-2360